GLN

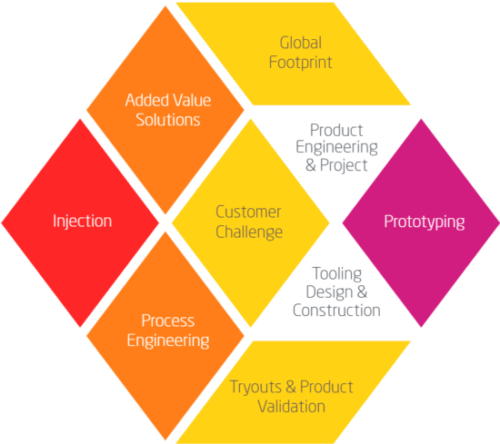

ONE-STOP-SHOP ECOSYSTEM

Customer Challenge

Having in mind the complete set of expertise of the GLN Group in terms of industrial product engineering & validation services, we are working closely with our customers so we can supply the solutions to their arising challenges. The aim is to always look for the greatest benefits we can offer to satisfy the customer needs.

Product Engineering & Project

Counting on a specialized team with years of experience in the mold and injection industry, we are able to work closely with customers in the development of new dedicated projects. These include: the product engineering in terms of shape by modelling 3D, 2D part to print, rheological studies, materials research, and others.

The goal is to get a product that can be injected and demolded from the tool through the combination of several concepts and technologies answering the customers’ needs.

Prototyping

GLN has the capability to supply several kinds of prototype parts that enable the pre-validation of the products and the market before passing into production molds and serial injection.

The partnership network that we’ve established, helps us in supporting our customers by supplying solutions from 3D printing (SLS, SLA), silicon or aluminum molds to low volume production molds.

Tool Design & Construction

Internationally recognized as a mold manufacturer of reference at European level, GLN’s years of experience, allow us to offer the best solution for the design and manufacture of high precision technical molds, using the combination of available technologies in a single tool. GLN counts with two modern production facilities where the latest generation of engineering and manufacturing equipment is employed at every stage of the process.

After the validation of the product, GLN studies the manufacturing methods to be applied into the mold through the DFM (design for manufacturing), adopting the more appropriate concept according to the technologies on which we have been specializing over the years.

The plants are supported by dedicated teams integrated in the following departments: Project; Programming; CNC machining; EDM, Grinding, metrology, polishing, benchwork and test.

Tryouts & Product Validation

After the completion of the manufacturing phases, the tool is put into an injection machine to validate all the works developed. For that, GLN has created its own trial center equipped with 6 injection machines with a tonnage ranging from 80 to 160 ton that allows in-house samplings, or even pre-series productions for our customers, guaranteeing a total process control.

Nearby has been set our metrology department that is working tightly with the trial center, providing the results obtained in the plastic parts injected from the tools through plastic part analysis and reports, dimensional control (2D & 3D Scanner) and also computed tomography.

Process Engineering

The process engineering team works as a single point of contact with the customers since the order until the delivery. This team has the knowledge and the capability to give major inputs during the whole process; through the rheological studies, they can provide improvements in the molding process, follow and control the established flow charts stages and idealize the perfect production conditions.

For the product validation we can use the following methodologies: 53P, PPAP; PSW or APQP, fulfilling all the requirements for a continuous production.

This team’s know-how, simplifies the conception stage of the tools, and has all the know-how acquired in this field that can be transferred into the design department, reducing the amount of interactions during the mold manufacture.

Injection

Three injection plants, two of them located in Portugal and one in México allows the GLN Group to continuously supply injected parts for the following industries: automotive; electric/electronic and packaging.

We have available 49 injection machines that are ranged from 22 to 450 ton, giving us the capacity to answer the demands on time and with quality.

Naturally, the experience obtained with the development of the injection process gives the group the inputs for the continuous improvement of the engineering phases, tool construction, trials, and so on, allowing us to offer even better industrial product engineering & validation services.

Added Value Solutions

Being a technology company with a wide experience in complex projects, the GLN Group has constantly invested in bringing to the customer the supply of added value products with the integration in the injection of technologies, such as, automated robotized cells, assembly lines, quality and control points.

The expertise we get permit us to develop with the client, not only the mold, but also the automation process associated.

Global Footprint

GLN has expanded its operations overseas, with the settlement of a plant in Mexico, which put us closer to our markets, reducing the logistical time as we are where the customers need produced parts.

The main destination of our products is Europe, North America, and China.

The goal is to continuously position GLN Group as a premium supplier in the supply chain of molds and plastic parts.