Entities

Leading Promoter

CloudiFacturing – OPTIMUM | Injection Process Optimization of Moulding Machines

Project Number | Grant Agreement N. 768892

CLOUDIFACTURING: Cloudification of Production Engineering for Predictive Digital Manufacturing

CloudiFacturing is European Innovation Action project under the Horizon 2020 a mission to optimize production processes and producibility using Cloud/HPC-based modelling and simulation, leveraging online factory data and advanced data analytics, thus contributing to the competitiveness and resource efficiency of manufacturing SMEs, ultimately fostering the vision of Factories 4.0 and the circular economy.

To pursue this mission, computationally demanding production engineering and simulation as well as data analytics tools are to be provided as Cloud services to ease accessibility and make their use more affordable.

CloudiFacturing is a project, which is open to new (teams of) participants (3rd parties). With their Open Calls, they are looking for / seeking innovative use cases in the context of the project’s mission.

OPTIMUM

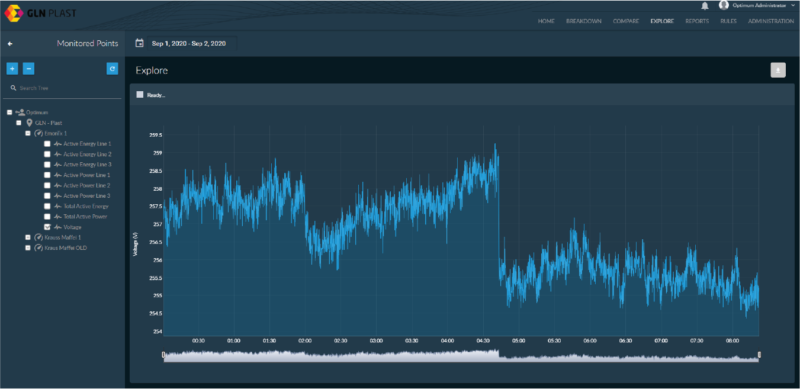

OPTIMUM is an experiment integrated in the CloudiFacturing project (3rd Wave) wich aims to cloudify data-driven and visual analytics tools for sustainable process optimization in the automotive plastic parts production, exploiting the HPC potential by applying model-based predictive functions (available at Pragma platform) to the injection process. Experiment-specific machine learning models, cognitive models and optimizations techniques will be coupled with advanced visual analytics leading to cost and energy savings and improved customer-focused flexibility. Thanks to that, new knowledge will be generated to feed product differentiation and rise of software-enabled offerings for smart factories.

The experimentation is carried on by the OPTIMUM consortium that is composed by three partners: the Portuguese GLN PLAST (GLN) is the experiment coordinator and acts as End User. Its objective is to integrate the developed technologies into the daily flow of work. As experts in plastic injected parts, the company is focusing in optimize the production process through the use of new technologies. Pragma-IoT IKE (Pragma) is a Greek company acting as ISV with the goal to provide Pragma platform (equipped with embedded intelligence) and parameterize and extend the existing algorithms (i.e. algorithms for malfunction and anomalies detection, predictions, abnormal behaviour detection, etc.) to implement the real time monitoring and the optimization of machine settings, production monitoring and energy consumption management. Finally, Energy@Work (E@W) is an Italian innovative SME that act as a VAR and system integrator, working on the activities related to the deployment of the solution on the CloudiFacturing Platform.

More

Implementation Period CloudiFacturing | 2017-10-01 to 2021-03-31

Implementation Period OPTIMUM | 2020-02-15 to 2021-02-15

Approval Date | 2019-12-20Total eligible cost | 128 625,00 EUR

Funding | | H2020-FOF-2017 / 99 937,50 EUR | 37 187,50 EUR GLN PLAST | 29 750,00 EUR PRAGMA-IoT | 33.000,00 EUR Energy@Work

Downloads