Partners

Leading Promoter

ADDITIVE MILLING | Add Milling to Additive Manufacturing

Project Number| POCI-01-0247-FEDER-003414 | Portugal Central

The use of electrodes as well as being expensive, is not environmentally sustainable. In the cases of producing complex geometrical areas, the problem is compounded by the need to divide the piece in small areas, involving many electrodes, more time, money and environment costs, in addition to the negative impacts on human health and ecosystems. The solution to this problem is the additive manufacturing. The key advantages are the efficient use of raw materials and consequent reduction of waste, the production of complex geometries with “free design”, allowing, the decrease in weight and the creation of functional parts in one single part. The customization, the speed of the project and the non-utilization of physical tools (Laser) turns this technology into the Technology of the future.

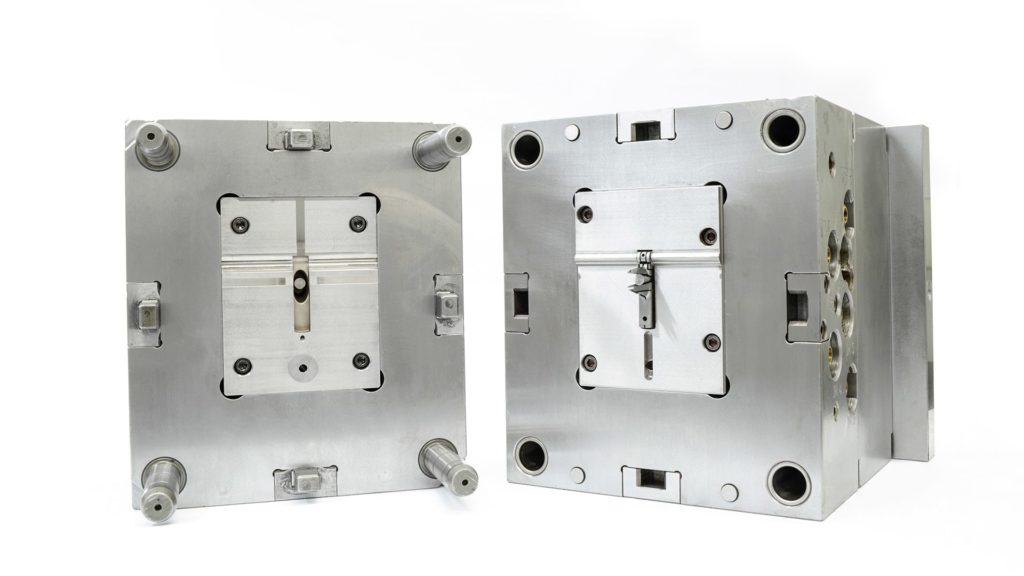

Selective laser melting (SLM) has been positioned as the twenty-first century metal processing technology. However, this technique has as its main weak point surface finishing.Thus arises the Additive.Milling project that aims to reconcile both additive and subtractive technologies in a step-by-step process that allows producing molds of high complexity with low coarseness without the need to purchase hybrid equipment.

More

Implementation Period | 2016-01-01 to 2018-06-30

Approval Date | 2015-10-20

Main Goal | Reforçar a investigação, o desenvolvimento tecnológico e a inovaçãoTotal eligible cost | 626.816,83 EUR

Funding | FEDER 105.679,10 EUR GLN MOLDS

Downloads